Reflections on the Last 6 Months.

As I reflect on the past six months, I find myself exhaling deeply, as if I’ve just completed a marathon and am finally catching my breath. It’s been quite a journey.

The path we’ve traveled has been filled with grief, triage, fear, frustration, overwhelm, uncertainty, scarcity, and the unknown. We’ve encountered situations where we had to accept that some things will remain mysteries, faced layoffs, tightened our belts, and bonded through shared experiences. There has been collaborative and deep work, pivots, tough conversations—many tough conversations—and, of course, meetings, meetings, and more meetings.

Yet, along the way, we’ve also found moments of laughter, excitement, and genuine reward. Just yesterday, I was working through yet another technical glitch with our dedicated board member and IT Steward, drp. Despite the frustration, we found ourselves joking that every task seemed to come with more challenges than we anticipated. It is nice to be at the point where we can laugh about the small things. We have come a long way in a short time.

I’m incredibly proud of our staff and board for coming together to support this community. I’m deeply grateful to everyone who has stepped up to help us. The strength of our community seems limitless, and it truly is the glue that holds Ace together.

The biggest challenge, as many of you know, is our budget. This is the mountain we’re currently climbing.

So, what have we been up to in our efforts to turn the tide?

- Welcoming and voting in a new board

- Promoting staff into roles that better support their work and creating detailed job descriptions

- Retaining our valuable staff with adequate employment packages

- Creating new educational opportunities and expanding class offerings

- Designing a sustainable membership model and crafting retention plans

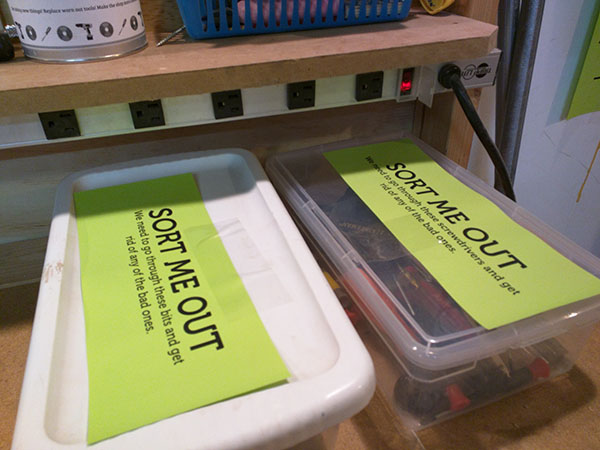

- Sorting out our software issues

- Designing a sustainable volunteer program

- Engaging members to help craft the future with us

- NDA revamp so volunteers can help us with administrative needs

- Creating email accounts and Slack channels focused on specific aspects of our work and community, ensuring that messaging doesn’t get lost

- Tackling our budget concerns

- Finalizing a budget for 2024!

- Planning a Gala event and Silent Auction

- Organizing ACE’s first public fundraiser

- Writing grants—lots of them!

- Holding a Town Hall

- Creating a pitch deck and plan to attract corporate donors & sponsors

- Building relationships

- Fixing website issues (though there’s still more work to be done!)

- Identifying and revamping systems and procedures that weren’t working

- Amping up our outreach efforts

- Holding monthly community get-togethers and open board meetings

- Hiring instructors for CNC and Laser

- Organizing our files and creating collaborative ways to work together

I’ll be honest with you, this has been a mental and emotional rollercoaster for the Ace team. Some of us are feeling a bit burned out and are taking a moment to rest, while others have picked up the baton and are running onward.

While we’ve been deeply focused on this work, we haven’t had the bandwidth to keep in regular touch.

I apologize for that. We’re making communication a priority moving forward.

I apologize for that. We’re making communication a priority moving forward.

We are a small but mighty staff with the heart of a powerhouse, even so, we are understaffed. Finding volunteers to help us with our communications will be helpful, but first, we need to get that NDA sorted out!

We’ll keep pushing forward—ACE is on the move!

Be part of our journey forward, volunteer (volunteer@acemakerspace.org), be engaged, donate, stop by and have lunch with us, and tell folks about Ace.

Onward!

Juliana

Your Interim ED

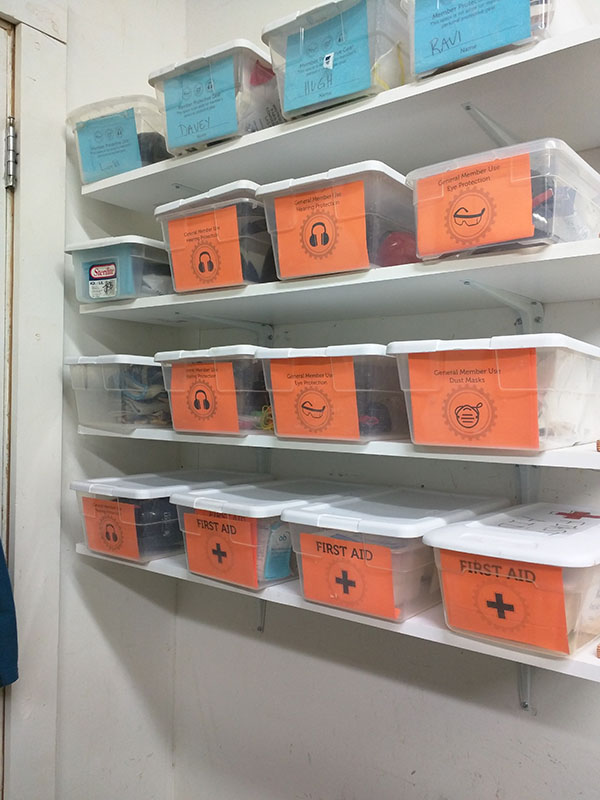

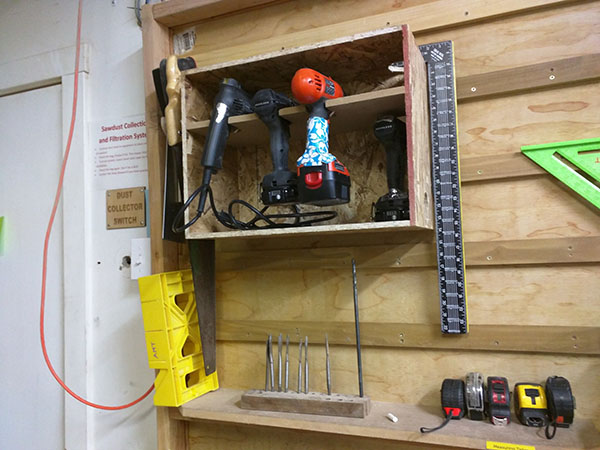

most recent purge of extraneous stuff. I borrowed a magnet from the fridge and hung it from a piece of string… which actually seemed to work better than the old stud finder. Two 3″ #8 screws hold my

most recent purge of extraneous stuff. I borrowed a magnet from the fridge and hung it from a piece of string… which actually seemed to work better than the old stud finder. Two 3″ #8 screws hold my