Martin has loads of furniture making experience, but this deep pour resin technique was totally new for him…

The idea for the project came from Martin’s friends who spotted a sleek resin pour table they liked on Four Eyes Furniture. They asked him if he could make them one so he watched a couple videos and decided to give it a go.

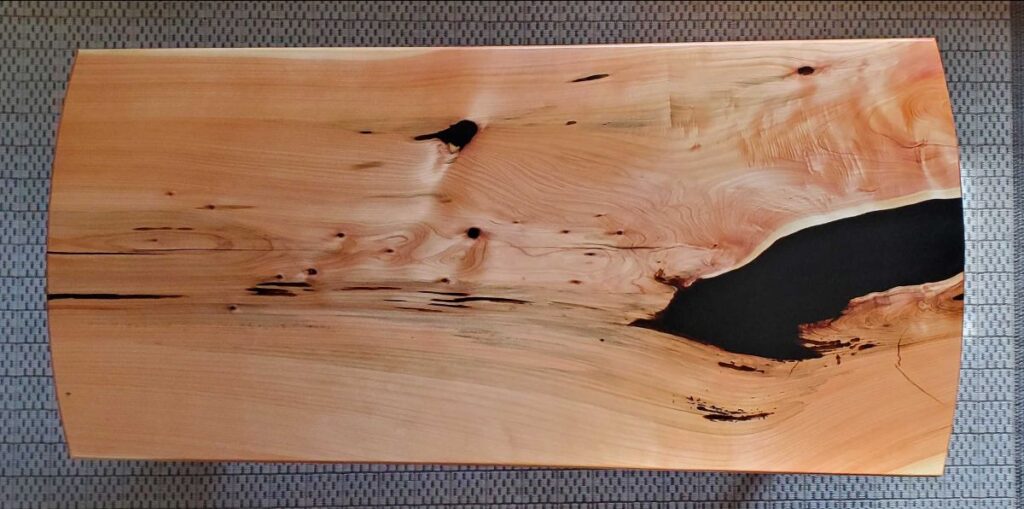

First, he selected a gorgeous slab of kiln dried Monterey Cyprus.

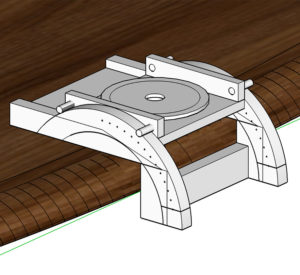

Then he purchased a gallon of Black Epoxy Resin and checked in with the Ace Workshop Community about using Clean Fab for the pour.

Martin filled the gaps in two rounds; first the top and then the bottom. Each pour took several days to cure before he hand planed it to remove extra resin from the surface.

Martin’s tips and takeaways:

- Resin costs $$$

- It takes time, patience, and a little planning. Each pour takes several days to cure.

- After the resin sets, planing the surface by hand is labor intensive. Be prepared to roll up your sleeves.

- Monterey Cyprus Wood dust is particularly irritating so well fitting PPE is a must

- He’d do it again, but mostly because he has extra resin…