Over the last year it has become evident that our fleet of 3D printers is showing its age. First I upgraded the Type-A printer with a new hot-end and LCD/SD card reader. It’s much improved, but still not reliably producing the quality I was hoping for. Meanwhile the Replicator 2 had an alarming number of maintenance issues. Among other things I had to completely replace the hot end, and add a ‘bypass’ circuit to get the extruder fan running reliably. I’ve managed to keep both printers working (they’re still in good order as I write this), but my confidence in their long-term prospects is not high. Rachel suggested I look into a replacement.

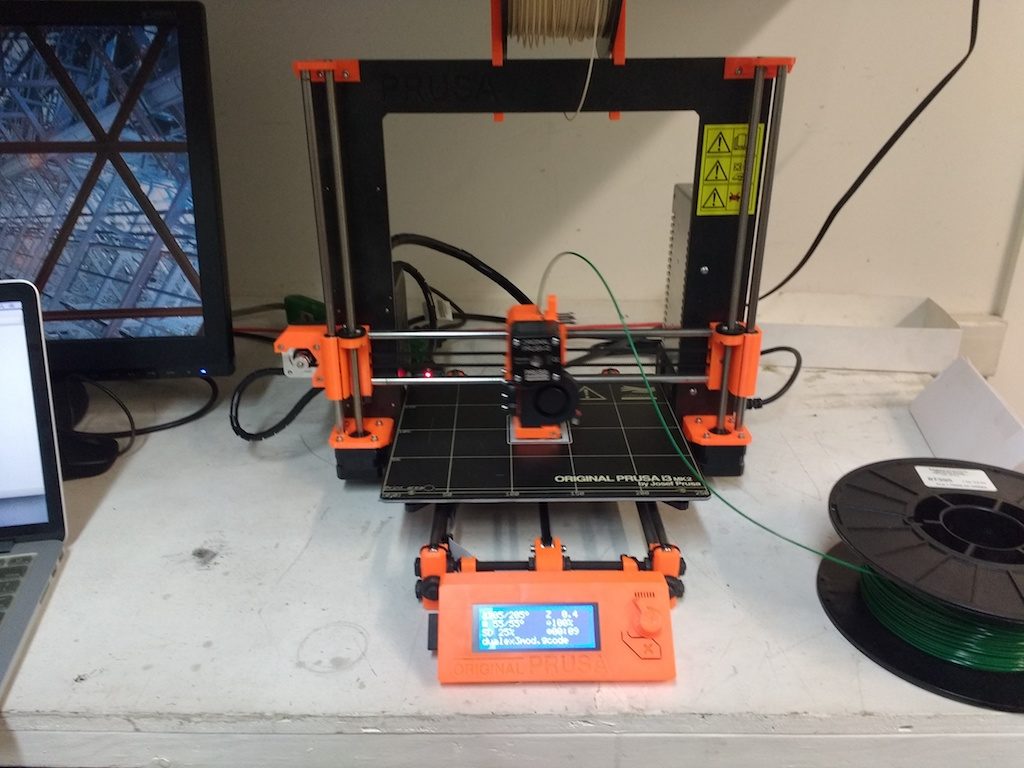

So, a few months back, I made a list of criteria and started searching in earnest. I’d originally thought about building a machine from scratch, but ultimately decided on the “Original Prusa i3 MK2.” It ticked off most of the boxes on my list, and has received rave-reviews. Ours has been assembled, tested, calibrated, and deployed for use for about a week now.

Why this one?

So, why did I choose this printer? …particularly when inexpensive printer kits can be had for less than $200.00 these days?

Well, the inexpensive machines sold on AliExpress and elsewhere are great deals for individuals who don’t mind doing a bit of fiddling around. I still recommend them if you’re on a budget, and am more than happy to help if you need it.

Personally, I’ve always wanted to understand how things work, and have always preferred to build something myself rather than buy it. When I first joined AMT, I figured I’d be surrounded by like-minded folks. We are hackers, right? Those $200.00 printers are for hackers.

But, much to my surprise, most folks I’ve assisted here at AMT have no desire whatsoever to understand the inner workings or finer points of our 3D printers. They just want to use the machine, with as little training as possible. So, reliability and ease-of-use turn out to be all-important.

The Original Prusa i3 MK2 is about the least-expensive 3D printer that fits the bill. It’s a substantial improvement over the older i3 design that most of the clones are based on. (I really think he should have given it a newer, more distinctive name.) It features:

- Automatic bed leveling! This addresses the number-one issue that plagues even experienced users here at AMT.

- A special edition of the open-source Slic3r program, preconfigured for all common filament types.

- A PEI bed surface for good adhesion and surface quality; no need for blue tape!

- A special heated bed with varying trace density for even heat (an i3 MK2 exclusive, as of this writing).

- Great documentation and support.

- A genuine RAMBO electronics board. This is probably the best 8-bit option available and features fuses on high-draw circuits.

- A genuine E3D hot-end; not a cheap knockoff.

- A machined aluminum frame with a rugged finish (many clones are acrylic).

- High quality stepper motors, precisely matched to their function.

- Precision lead-screws on Z-axis, integral to the stepper motors (no wobbly coupling nut).

- Printed parts of the highest quality.

- Well-thought-out wiring paths; no dangling cables.

- Firmware that includes self tests, auto calibration, …even corrects for out-of-square assembly!

- The entire design remains open-source in case replacement parts must be 3d printed. I damaged a minor part during initial assembly and was able to simply print another.

Besides all that, Josef Prusa has probably done more for open-source 3D printing technology than anyone. He and his company deserve our business.

Training now required

I host training sessions all the time, but we’ve never actually required training to use our 3D printers. They’re not all that difficult to use, and there’s little risk of hurting yourself.

But, during my tenure here (about a year now) I have run into a number of users who really should have had proper training. In some cases they risked damaging the machines. So I suggested that we tighten this policy up at a meeting a few months ago and got enthusiastic support. Starting now, training is required.

While the i3 MK2 is certainly the easiest of our printers to use, there are a few important things to know. Training only takes about 30 minutes or so, and will henceforth be the first thing we do at every 3D Print Hangout (every other Monday night). I’ll also schedule a few extra “training only” sessions so that everyone has a chance to attend. Training is free and open to non-members as well. If you can’t attend a regularly-scheduled training, get in touch and I’ll work something out.

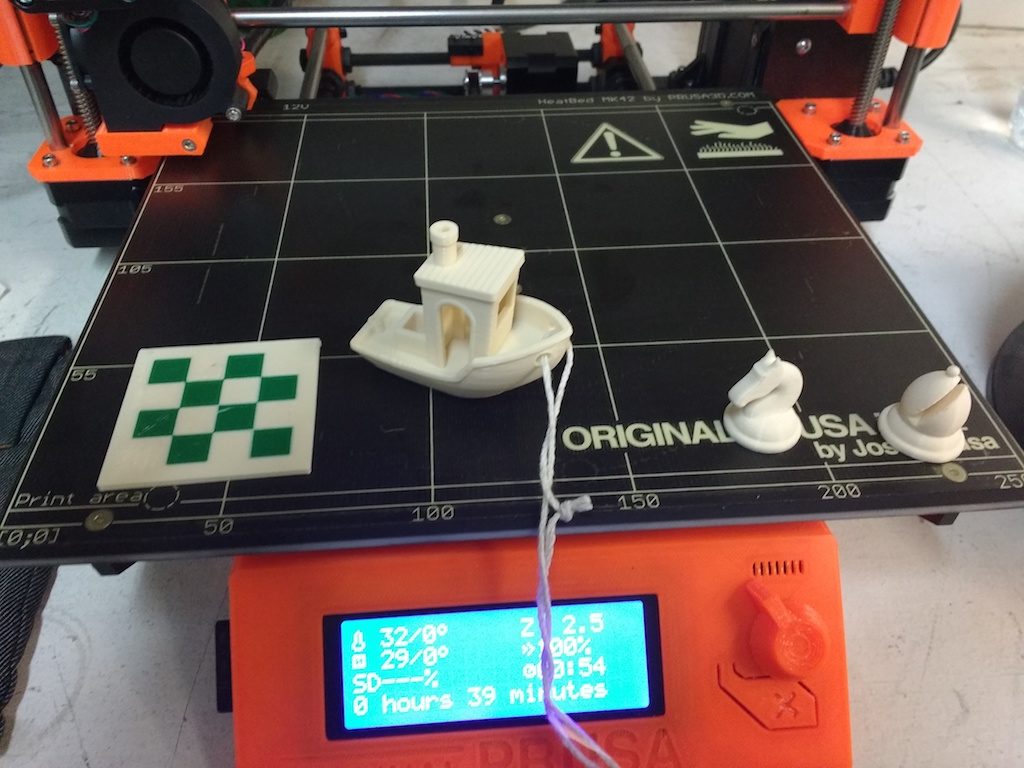

I hope you have fun with the new machine! We’re getting great results so far!

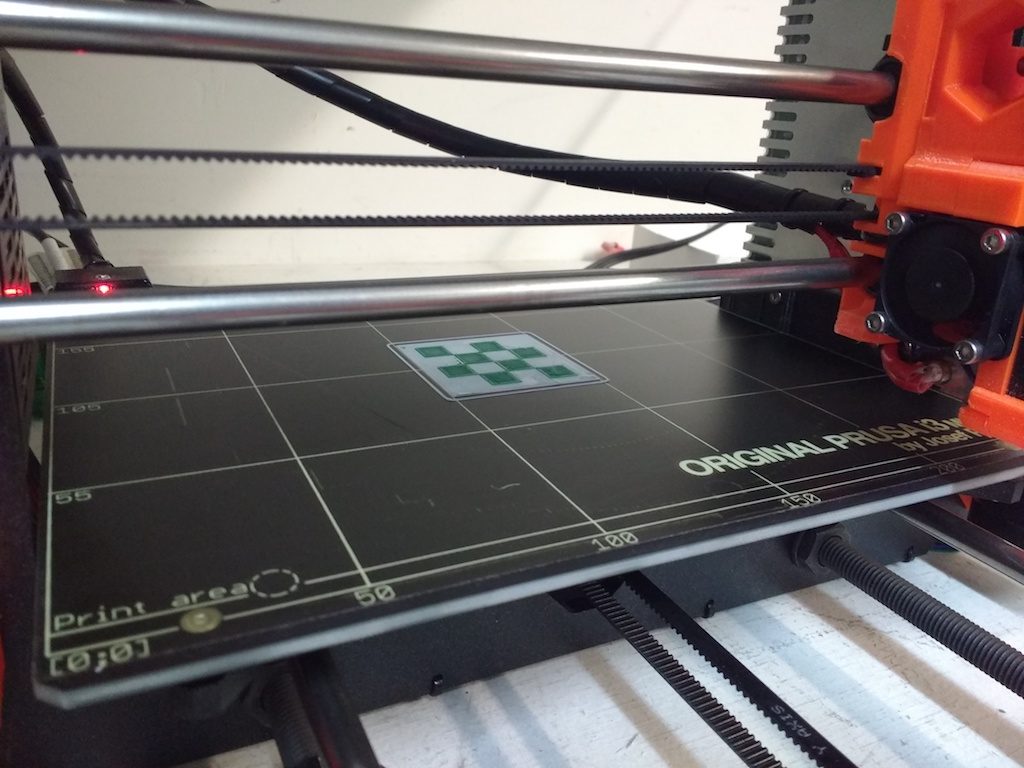

Oh, by the way: This printer does not feature dual-extrusion, but there is a spiffy ColorPrint utility that allows you to pause the job at a specific layer and change filament. It works great and is lots of fun to use! I used it for the AMT logo in the photos. (The checkerboard used a related but experimental technique… watch for a future post on the subject!)