Last nights ‘3D print design’ meet up was attended by just two guests! Enric and Don. Nonetheless, we had a very productive session.

Don was a complete newcomer and simply wanted an introduction to it all. I printed a bevel gear and walked him through the process. The gear was created by a Fusion360 macro I’ve been working on… I’ll show it off at an upcoming open-house when it’s done.

Enric had a very interesting project that really shows off 3D printing’s potential for solving everyday problems. Several of the windows latches in his house have broken. Unfortunately the parts aren’t manufactured anymore.

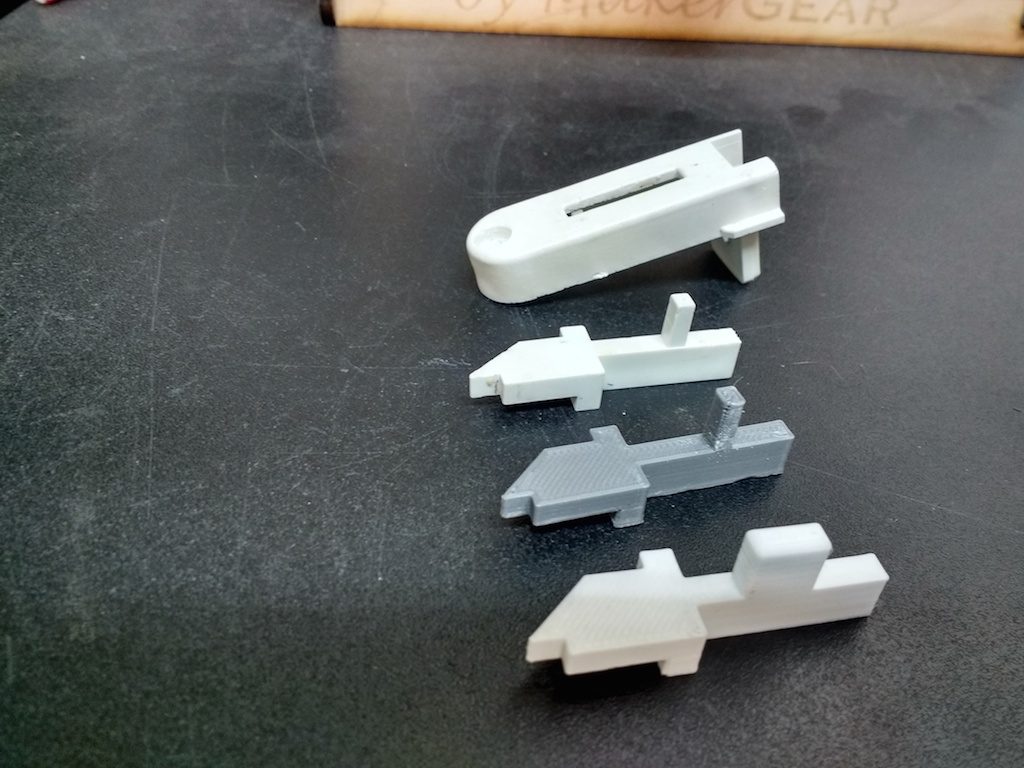

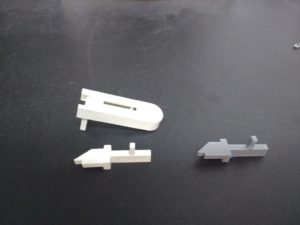

He found one that is still intact, removed it from his window and brought it along. After some careful measurements (Enric brought his calipers too), we were able to create an accurate model in Fusion360 and print it.

The part fit on the very first try (the gray part in the photos). I feared that the small projection used to slide the latch might be a bit weak, and upon examination we found that the housing would allow us to simply enlarge that portion. It gave us a good excuse to revise our model and reprint, showing off the benefits of a parametric modeler to best advantage. We switched to a better color while we were at it. The new piece seems to fit just as well as the first.

But, does it work? It seemed okay in the lab, but we’ll have to wait for Enric’s installation report! Enric?

Here’s the Fusion360 model if you want to have a closer look.