There have been some troubles with the CNC not following Gcode paths exactly and rounding corners.

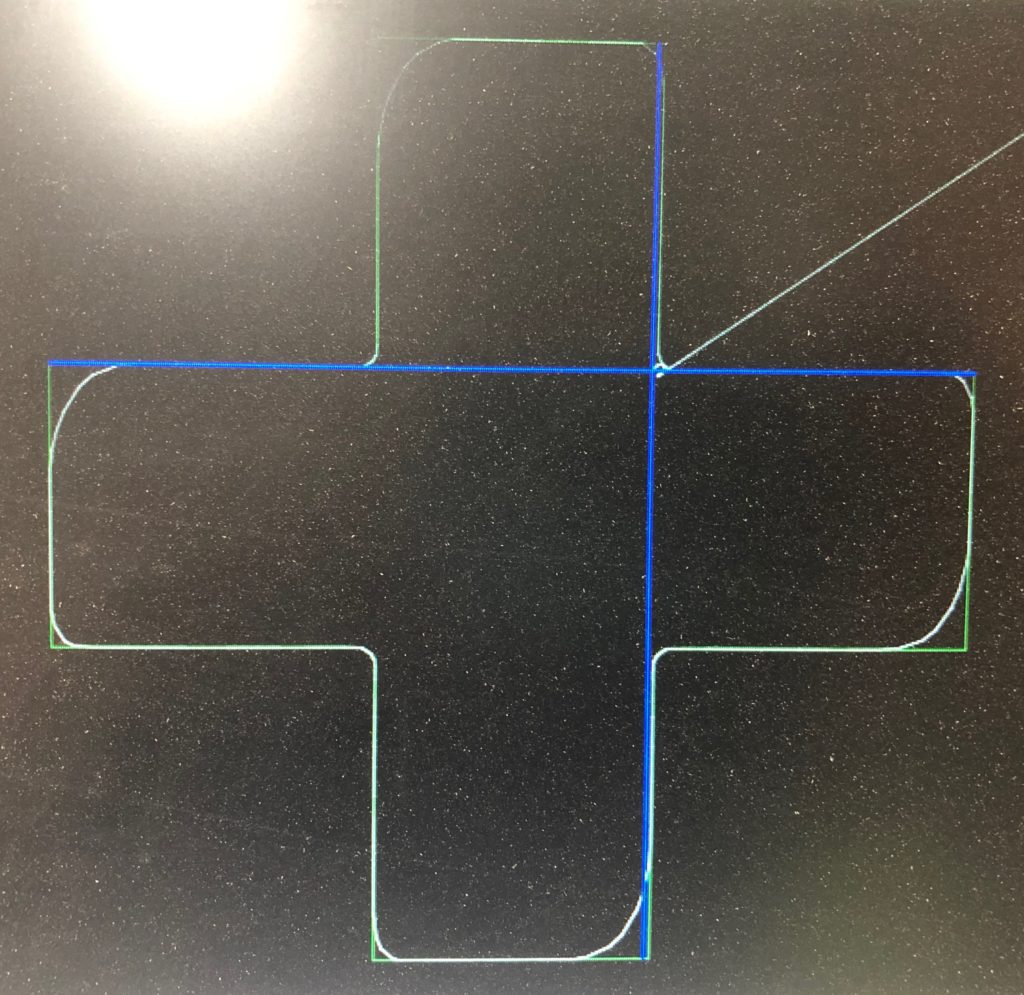

In this first picture of the Mach4 screen you can see the green lines which are the path the CNC should follow, and the white lines which are the path the CNC actually followed. (ignore the blue lines)

The problem is the CNC is rounding over the outer corners. This is a result of the CNC trying to move faster than it can manage. The max speed of our CNC is 200 inches per minute. In the above picture it is trying to cut at 150 IPM and can not handle that speed on the corners so it rounds them, which can ruin the piece. Even though the CNC can go faster in a straight line it can’t change directions that fast.

The solution is to use a slower feed rate. But this can greatly increase cut times and other issues such as tool dulling and excess heat.

Fusion360 has a solution called “Feed Optimization”. What it will do is reduce the speed in just the corners to 25% of the feed rate. In this example it reduces the corner feed speed to 37.5 IPM.

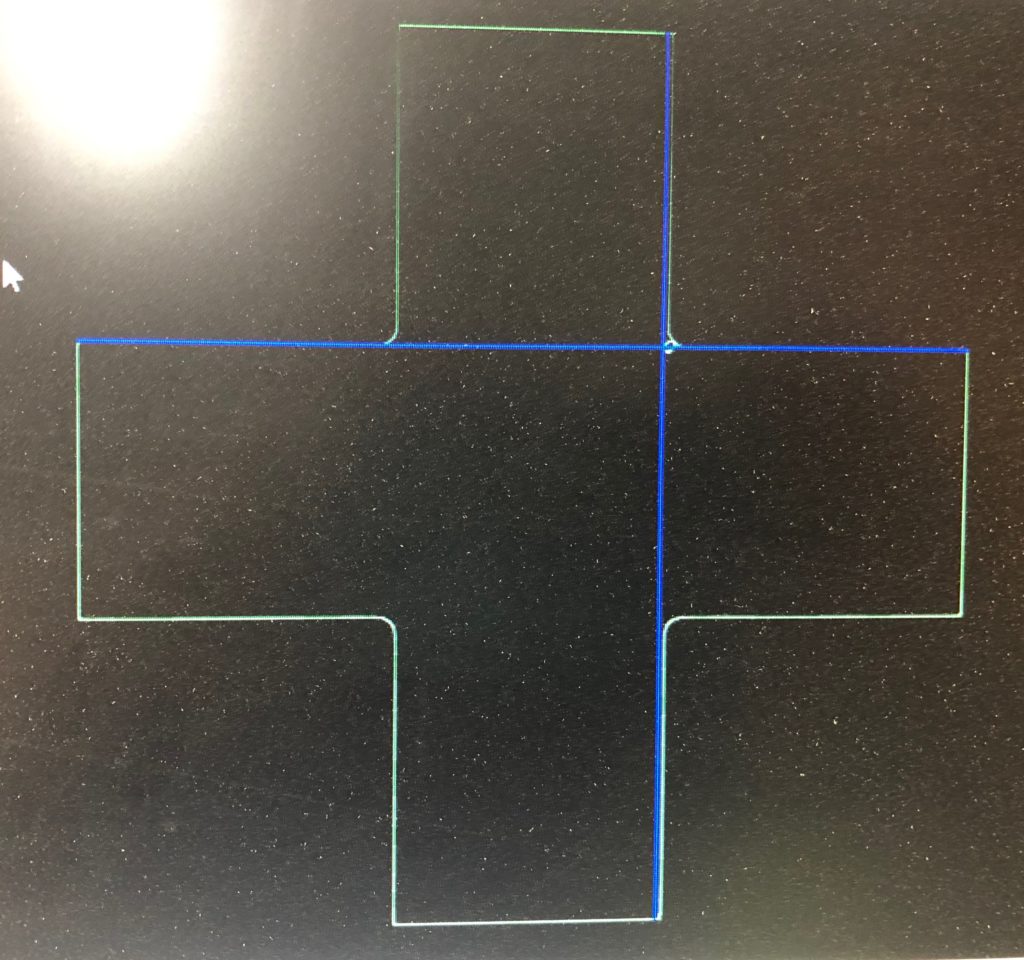

In this next picture you can see the white line of the actual cut path looks identical to the green Gcode path with Feed Optimization turned on.

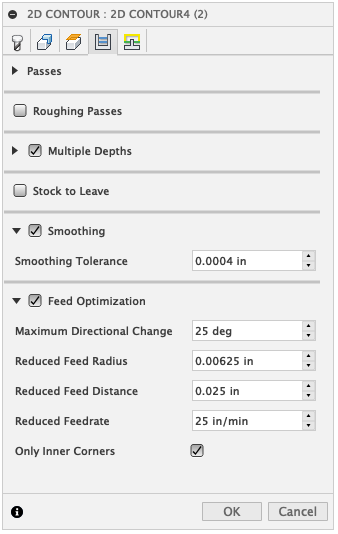

The Feed Optimization setting is found on the 4th tab (labelled Passes) of the Operations Dialog when you are in the Manufacture workspace.

In the bottom of this picture you can see the checkbox to turn it on. The defaults should be fine and will reduce your corner speeds to 25%. This only adds a small amount of extra time to the cut.

This project was set to 100 inches per minute so Feed Optimization reduced the corner speed to 25 IPM.

Mouse over each setting for an explanation of what it controls if you would like to fine tune even more from the defaults.

Thanks Rabbit!